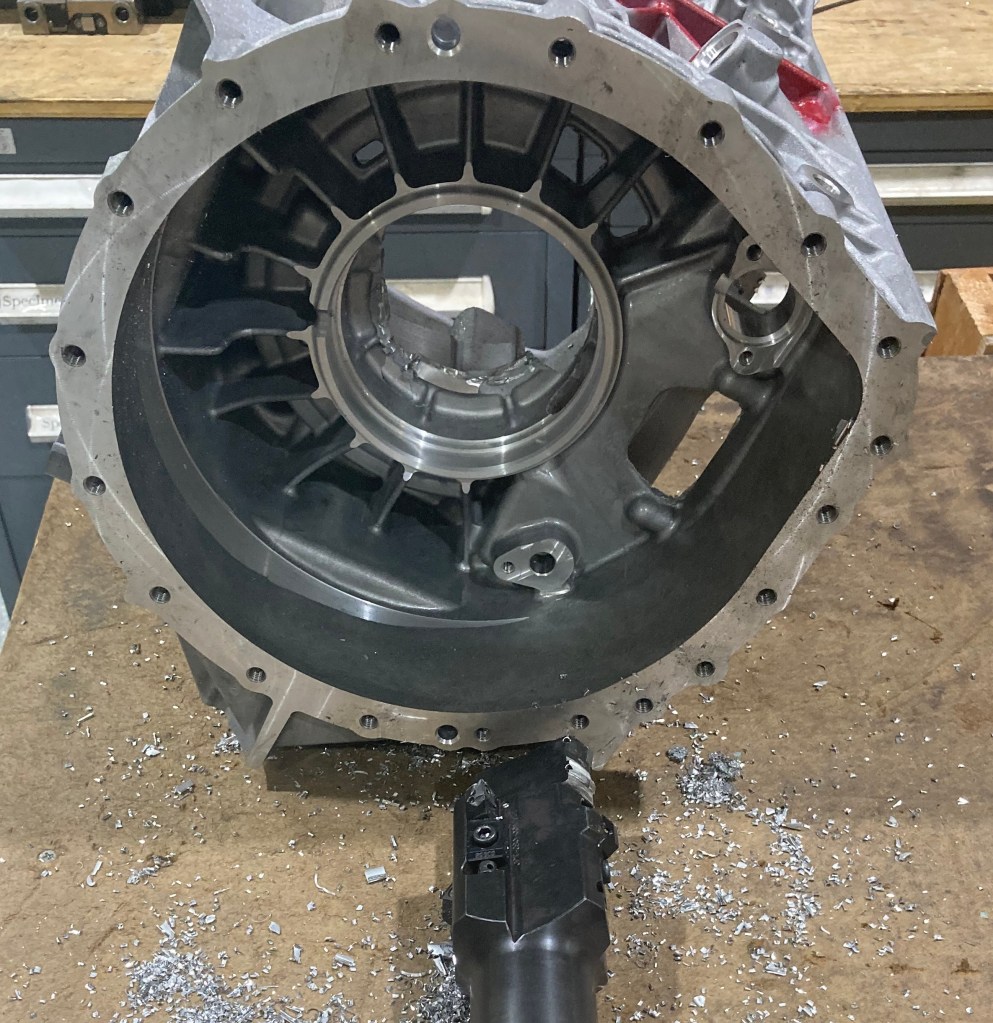

Welcome. This issue’s cover shows a prototype case for an F-150 Lightning drive unit set up for testing on an auto-clamping fixture. Like a transmission case, it’s basically a glorified trash can. The “300” etched on the part indicates that the exposed surface is the 300 face; you can also see a “500” on the face to the right. All faces on a prismatic part are numbered in the hundreds, and the holes on the 300 face are numbered 301, 302, etc. Near the front of the part print file is a hole chart with aspirational descriptions of the holes on each face. If you have a professional interest in drills, this is the first thing you look at, and it’s often an emotional event due to idiotically tight proposed tolerances, dreamed up by Platonists who’ve never even made a birdhouse.

Test parts are always painted so that people will know not to send them to assembly to be put in a car. Usually they’re red but this one is blue, no doubt for some advanced engineering reason such as a shortage of red spray paint in the crib. Incidentally, if you have a mid-90s Camaro that pulls to the right a little, it might be from some test steering knuckles I drilled that mysteriously disappeared on the way to the measurement room.

The drive unit machining launch team worked on machines in our shop to fine-tune things while equipment was being installed in the plant. I wasn’t involved except as a consultant on tooling and vibration issues. Everyone in the car business is always in a hurry, and as you turn up the speed on machines you can get unstable vibrations in the structure unless you first characterize the dynamics of the system, which requires uncommon instrumentation and training. Aside from a crash that destroyed a machine spindle it was an uneventful project. The launch team attracted a steady stream of sales reps, so we weren’t short of donuts. I would sometimes tell a sales rep with a box of donuts that their main competitor had brought steak sandwiches the day before.

My plans for future covers are as follows: 2025 will feature internal combustion powertrain or driveline components (block, head, transmission case or axle carrier), 2026 will cover non-automotive projects from my aimless wandering period (plus maskmaking during the pandemic), 2027 will showcase machine shop and tool room folk art, and 2028 will be the Year of the Gear, a celebration of the exceptional beauty of gear cutting machinery. I’ll worry about the covers after 2028 if Pulsebeat is still in business and I’m still the editor.

The classical prototype for these notes is Extracts from Chordal’s Letters, the Odyssey of machine shop literature. (There is no Iliad, although Rivethead has some Homeric passages.) The reading period for Pulsebeat 10, which will be posted in January 2025, begins October 1. Until January, enjoy the wonderful poems in this issue.